Care Facilities

Efficient Laundry Management for your workwear

The optimal system for workwear management

You, as a resident director, housekeeping manager, or person responsible for several care facilities, want to be sure that your employees always work with hygienically impeccable garments. With a laundry management system you can control whether they comply with the hygiene concept and at the same time put aside some other problems:

- High administrative effort

- Time-consuming and costly

- Bottlenecks in the laundry supply

- Laundry has to be bought again all the time

- Garments are stashed or disappear

- No overview of availability

With the deister electronic laundry management solution teXtag – especially for the healthcare sector – you can easily automate the dispensing, return and management of workwear and transparently map the entire laundry cycle in the future. For both centralised and decentralised dispensing and return of workwear, this includes the removal of dirty laundry to the external or in-house laundry and the delivery of the processed garments. The Commander Connect software can automatically transmit order and collection processes to the textile service provider, e.g. if the stock falls below a previously configured minimum level. This solution simplifies the process for your employees, reduces the overall administrative effort in your care facility and ensures seamless inventory control and more planning security – that‘s what we call economic efficiency.

Why a laundry management system?

Minimize risks

Check the specified wearing times and change cycles.

Quick and easy

The removal and return of clothing is fast, simultaneous and user-friendly.

Relieve your employees

Avoiding supply bottlenecks and empty shelves thanks to gained transparency.

Increase efficiency

Reduce shrink, administrative costs and optimize laundry inventory.

Transparency and control

Keep track of textile inventory in real time 24/7.

Automation

Time optimization through automation in the laundry output.

Why you need such a system now

Workwear is increasingly becoming a sign of distinction and therefore requires special hygiene and control.

By using our solution to control whether your employees use fresh garments on a daily basis, you can actively support or even improve your hygiene concept.

You can specify the laundry change cycle and check whether everyone keeps to it. The software keeps complete track of all laundry movements. Furthermore, thanks to our laundry cabinets, there will be no more garments lying around openly on shelves or in lockers, where viruses and bacteria can easily spread over time. Using our software, you can check how long an item has been in the cabinet and see which are no longer fresh and may already be contaminated before they have even been used.

texCabinet

TCD 200 (Dispensing)

These laundry dispensing cabinets are designed for rapid access. Simply hold your ID card in front of the reader integrated into the door handle and take out your laundry in less than five seconds. Access permissions are easily managed by our software.

texReturn

TCR 50 / TCR 200 / TCR 250 (Return)

To return laundry, the user simply drops the laundry through the opening in the return cabinet. The laundry is automatically recorded by the cabinet. The laundry bag can be replaced in a few simple steps. The laundry return units from model TCR 200 upwards are suitable for all common mesh container types. Depending on the texReturn model, between 150 and 300 garments can be returned. TCR 250 and TCR 300 are equipped with a flap which can be adjusted in three steps. As an option, it is possible to lock the flap electronically and release it via ID card and reader.

Intelligent UHF transponders

Each garment is marked with a UHF transponder. This electronic tagging enables automatic management of the garments and documentation of the life cycle.

A textile transponder is essential and absolutely necessary for the introduction of an RFID-based laundry management system. Here, the transponder from deister electronic does not necessarily have to be used. We are also able to integrate most of the transponders commonly available on the market into our system.

We accompany you from the beginning to the end

Individual project planning and consulting including service and support services

You have certain ideas, conceptions or specifications – we have the corresponding know-how to be able to implement your individual wishes.

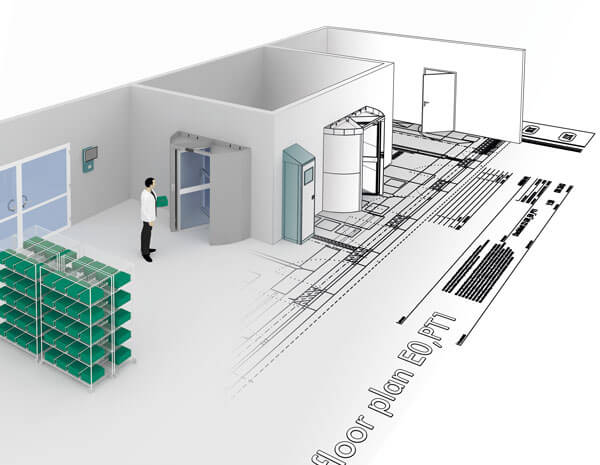

From the feasibility check and space planning to the visualisation and installation of the laundry dispensing system, we are by your side with advice and support from the very beginning to enable the most transparent and best possible management of the entire laundry cycle.

Our focus is on maximum user-friendliness, high speeds in the dispensing and return process, reliable recording of employees and garments within these processes, and low space consumption.

Of course, we are also there for you after the installation! If there are any problems with the system, if it fails or if you simply have questions about the installed system, we will always be there to help you.

- Implementation of custom-fit 3D visualisations

- Service & Support

- Training & briefings for technicians & employees

Test-System

Test the usability and performance of our laundry management system at any time in our demo room. Here you can operate and test all the products and applications of the solution yourself.

You would rather test such a system under real conditions? No problem! We can gladly arrange an individual test situation, just contact us.

Installation, commissioning and training

We personally ensure that the system is professionally installed and put into operation. This is accompanied by administrative training on the hardware and software before your employees are then instructed in how to use the system.